VCSEL Epi-Structure

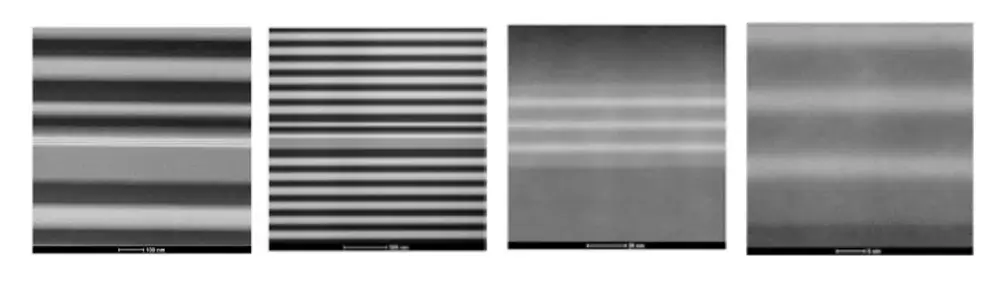

Most current applications use VCSELs in the IR spectrum. VCSEL device is a laser die based on a semiconductor material and comprised of epitaxial layers grown on n-type GaAs or InP substrates. The epitaxy is performed by molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD). The VCSEL structure, which is only a few micrometers thick, includes Fabry-Perot (F-P) cavity (resonator) with several active quantum wells as well as top and bottom DBRs (Distributed Bragg Reflector).

The quantum wells active area is where the electrons and holes are injected, combine, and emit the recombination energy as light, which then further oscillates perpendicularly to the layers in-between the DBRs. The DBR mirrors are composed of a stack of semiconductor layers that reflects the light only a particular range of light wavelengths to contribute to light resonance and to allow for the laser action.

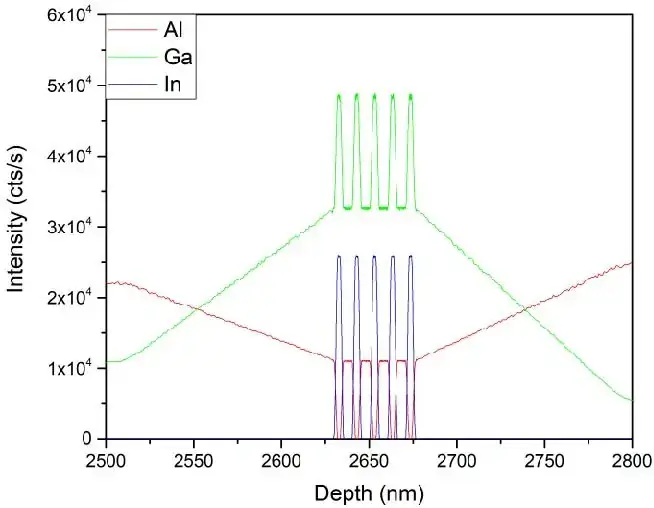

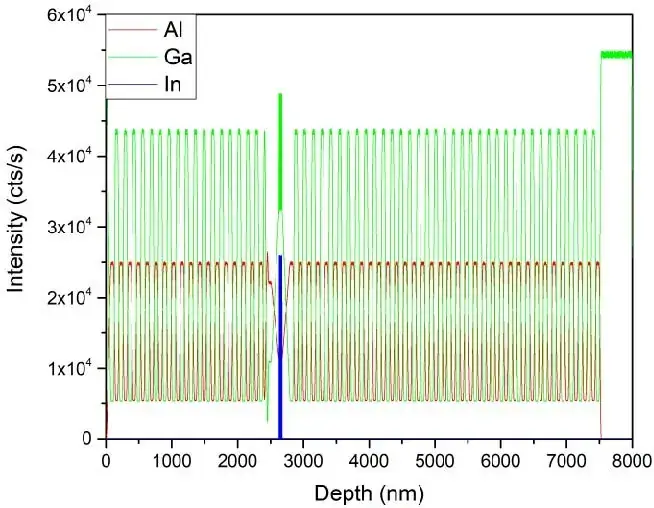

Owing to the large number of epitaxial layers and their complexity, the VCSEL is one of the most demanding epi-structure to grow among compound semiconductor epitaxial stacks. The whole epi-structure is about 7 microns thick (which is regarded quite thick) and it consists of more than 200 layers. One of the greatest challenges is the extremely high precision – with a single nanometer accuracy – in layers thickness control (cavity, DBRs, MQWs) in order to rightly position the resonance dip, as required by demanding telecom applications.

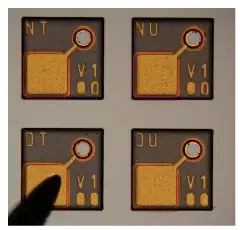

Vigo’s VCSEL laser die

VIGO’s VCSEL device has been developed to successfully demonstrate the capability to meet the increasing demand of our customers for disruptive epi-wafer technology.

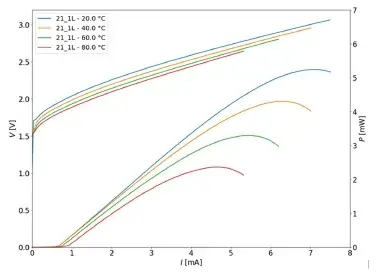

With optical power > 4mW, low threshold current of 0.6 mA and proper spectra characteristics, this particular 850 nm VCSEL epi-structure is suitable for telecom and datacom optical applications. Compared with other infrared technologies, VCSELs offer highly efficient optical beam, excellent focusing and a very small footprint. Because VCSEL emits light perpendicular to its top surface, a VCSEL chip can be integrated

in a single, two-dimensional array, consisting of several hundred individual apertures.

Apart from the VCSEL 850 nm, VIGO is committed to developing the technology of other wavelengths such as 760 nm, 940 nm, 1390 nm, and 1550 nm both for mass production and custom, innovative applications.