Anti-fringing technology

Laser absorption spectroscopy

Laser absorption spectroscopy is of great interest for gas detection in a variety of applications including: security, industrial process control, environmental protection and healthcare.

Optical spectroscopic techniques in general, and laser-based techniques in particular, offer a high speed and a high precision capabilities for detection and monitoring of numerous gas species.

Unfortunately, signal fluctuations (noise) are strongly influenced by the presence of optical fringing effects (also called etalon effects) – which is a limiting factor in a laser absorption spectroscopy.

Optical fringing is determined as the local signal amplitude to its mean value ratio

(see Figure 1).

Optical fringing is a result of the interference of radiation reflected on the optical elements.

The interference fringes stem from the optical system (Fabry-Pérot etalons between reflecting or scattering surfaces such as mirrors, lenses, optical fiber end faces, components of multipass cells, detector and laser package windows and semiconductor structure surfaces).

In VIGO infrared detectors fringes are generated mainly in GaAs substrate, due to its high refractive index (n = 3.3).

Fringing increases significantly for radiation wavelength above λpeak. This is due to the weaker absorption of long wavelengths in the absorber, so that more radiation is reflected from the metallization of the detector structure, contributing to greater fringing (see Figure 2).

Figure 2. Theoretical calculations of fringing vs. wavelength in standard IR detector illuminated by coherent radiation

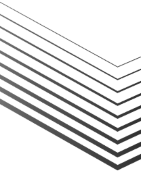

Figure 3. Fringing in standard detector (red line) and in detector with antifringing technology applied (dark-blue line)

Figure 4. Normalized spectral characteristics of the standard detector (red line) and detector with anti-fringing technology applied (dark-blue line)