In the period of increased product supply, the quality of products delivered and the way they are presented become more and more important.

Intelligent sorting is a mechanized solution that enables accurate sorting of products. The automation of the sorting process increases production capacity. This has a direct impact on profit, and, thus, on the quality and capacity of the products delivered.

Today, it is difficult to imagine a world without plastics - plastic objects are used in every area of our lives. The production of plastic products is much cheaper than the use of natural materials, moreover it is much faster thanks to advanced production methods. Plastics are materials that have been made by man from non-naturally occurring synthetic polymers or natural polymers (modified using appropriate additives). Colloquially, these types of materials are referred to as the collective name "plastic", but you have to remember that this is a big simplification, which does not take into account the differences between individual types of polymer materials. The need of transparent, completely water resistant and with many other chemical factors raw materials turned out to be a turning point for the industry. This translated into a much greater availability and lower price of a single item. Development of effective methods for the mass production of plastic objects has revolutionized many industries, but what about mass recycling methods?

There are many possibilities how to use recycled materials. A recycled plastic can be used to make: water bottles, pipes, furniture, auto parts and much more. Having said that, the need for proper detection of plastic is growing every day. Traditional plastic sorting deals with problem how to distinguish specific plastic types. Even small portions of the plastic element can reduce the effectiveness of recycling. Additionally, the problem of plastic sorting is not only affecting land trash but also marine debris.

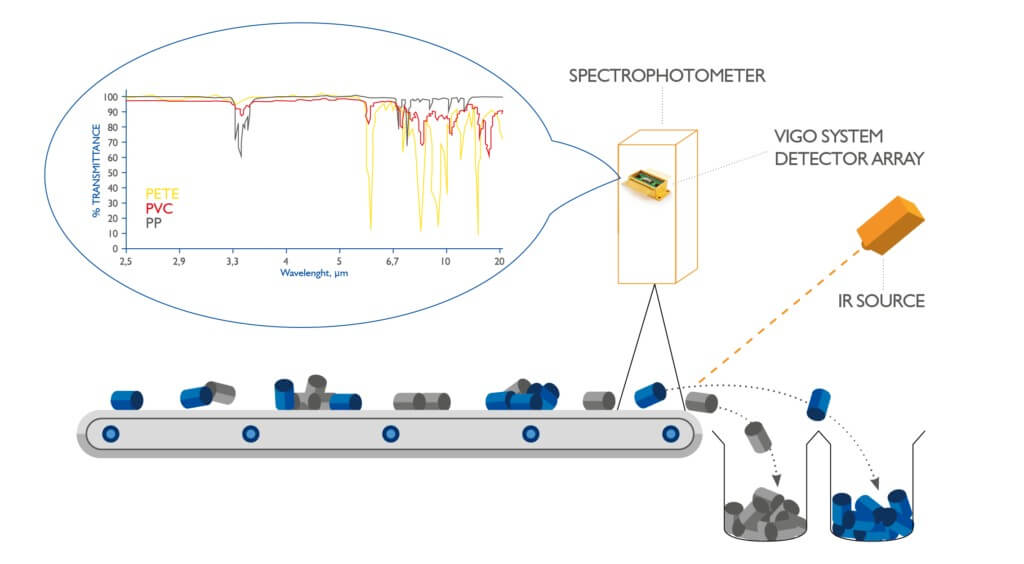

One way of plastic sorting is to do it on a sorting lane [Figure 1]. Firstly, we need to cut plastic into small fragments. Secondly, the small plastic parts are measured. Lastly, correctly identified plastic parts are put in the separate hole with air jets. Later on, this process can be repeated to deviate on different plastic types like: PETE, HDPE, PP, etc.

Figure 1. Example of sorting plastic by using VIGO detectors.

The simplest yet very accurate method for identification and classification can be made with spectrophotometer methods such as FT-IR. In FT-IR method IR light is illuminating the previously fragmented plastic parts. Reflected light is collected by the spectrophotometer system where thanks to detection by the VIGO detector we obtain a signal. Later this signal is transformed with Fourier Transform in order to obtain specific information about scanned material [Figure 2]. The analysis is quick and precise.

Each type of plastic has its own absorption bands which can be used for material identification. VIGO’s linear detector array can differentiate all types of plastic through a detection of these characteristic absorption bands [Figure 2]. The principle is visible below.

Figure 2. The method of measuring plastic by FT-IR. The chart shows examples of absorption bands of various plastics.

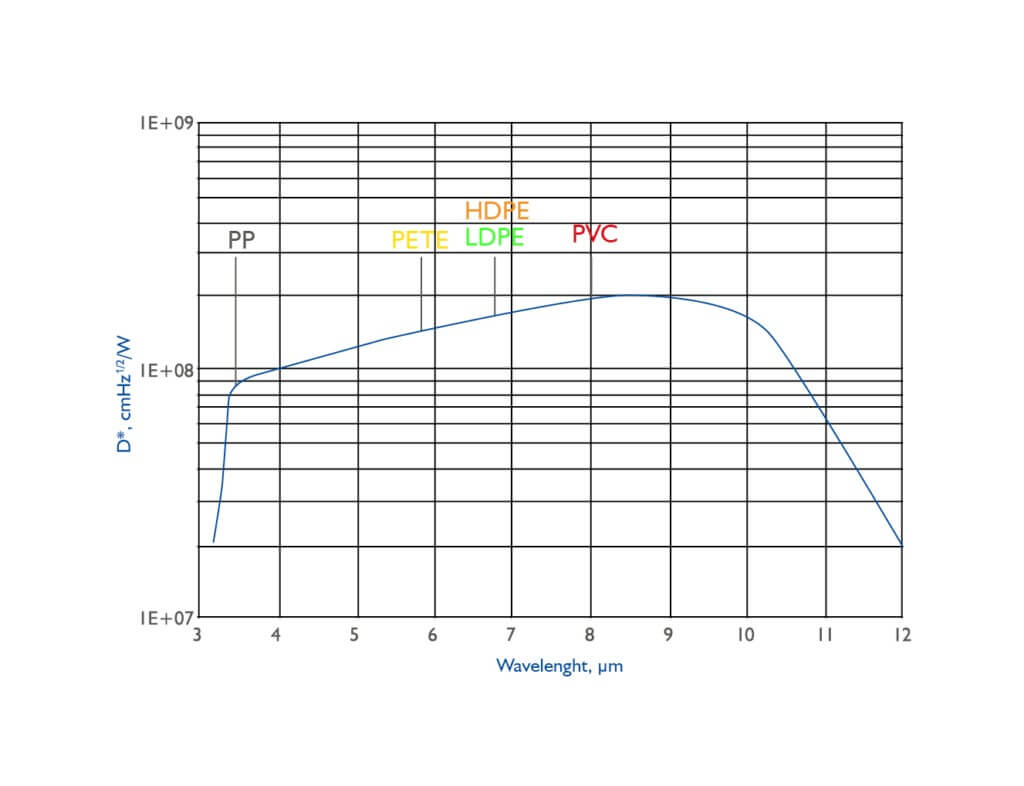

By detection of each marked absorption band the VIGO detector can “see” a type of the measured plastic. Organic compounds like polymers can be observed more precisely in the MWIR range in comparison to the NIR range.

The use of multielement detectors in spectrophotometry allows to eliminate moving parts or filters. This simplifies the spectrophotometer and increases system reliability.

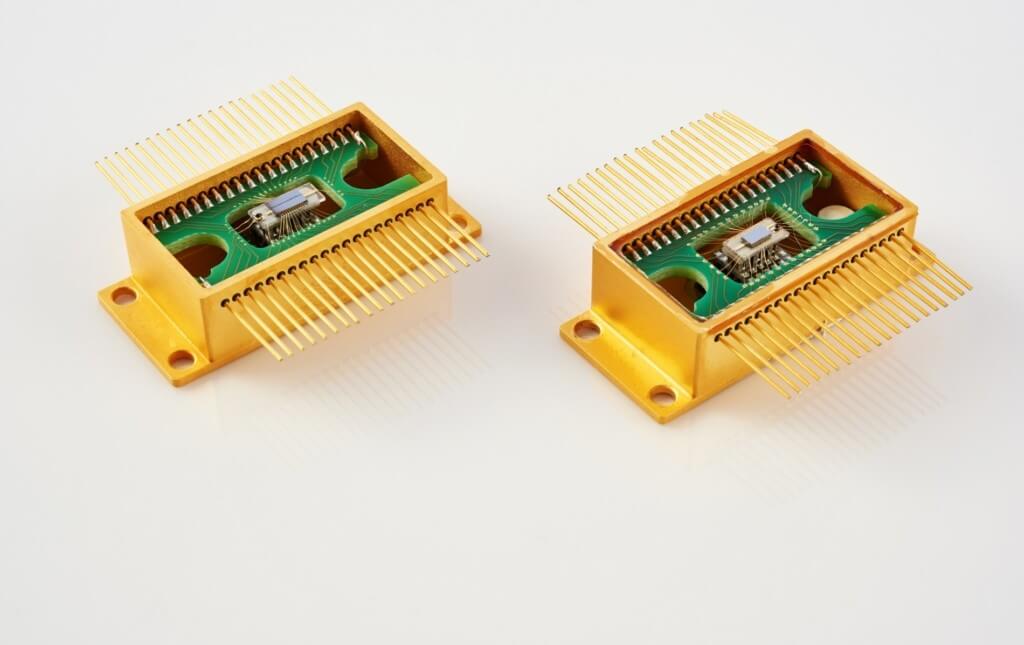

A 32-element linear array detector is recommended for OEM spectrophotometer for each polymer absorption band. Key benefits from using linear array detector include:

- Elimination of moving parts and/or filters

- High separation accuracy due to high SNR ratio

- High speed measurement

- Low power – uncooled detector

MID-IR Multielement MCT/InAsSb detector features

- 3-14 um wavelength band

- High S/N ratio

- Low drift of output signals

- High frequency operation

Module configuration options

- USB digital interface

- Customized mechanical layout

- Microprocessor inside

Figure 3. VIGO’s detector detectivity and some examples of absorption bands which can be used for plastic identification.

Mazowsze/0090/19-00