VIGO Photonics

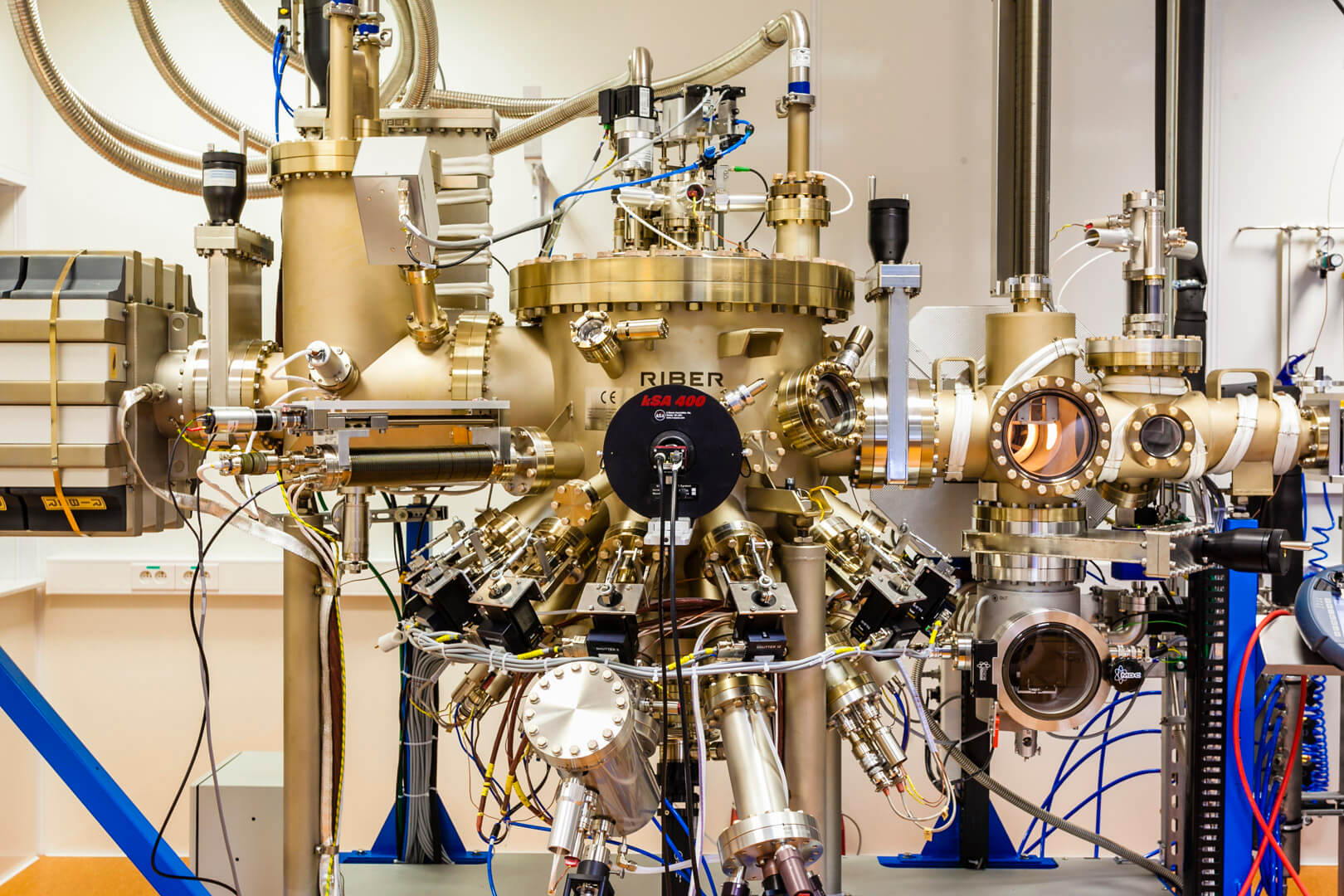

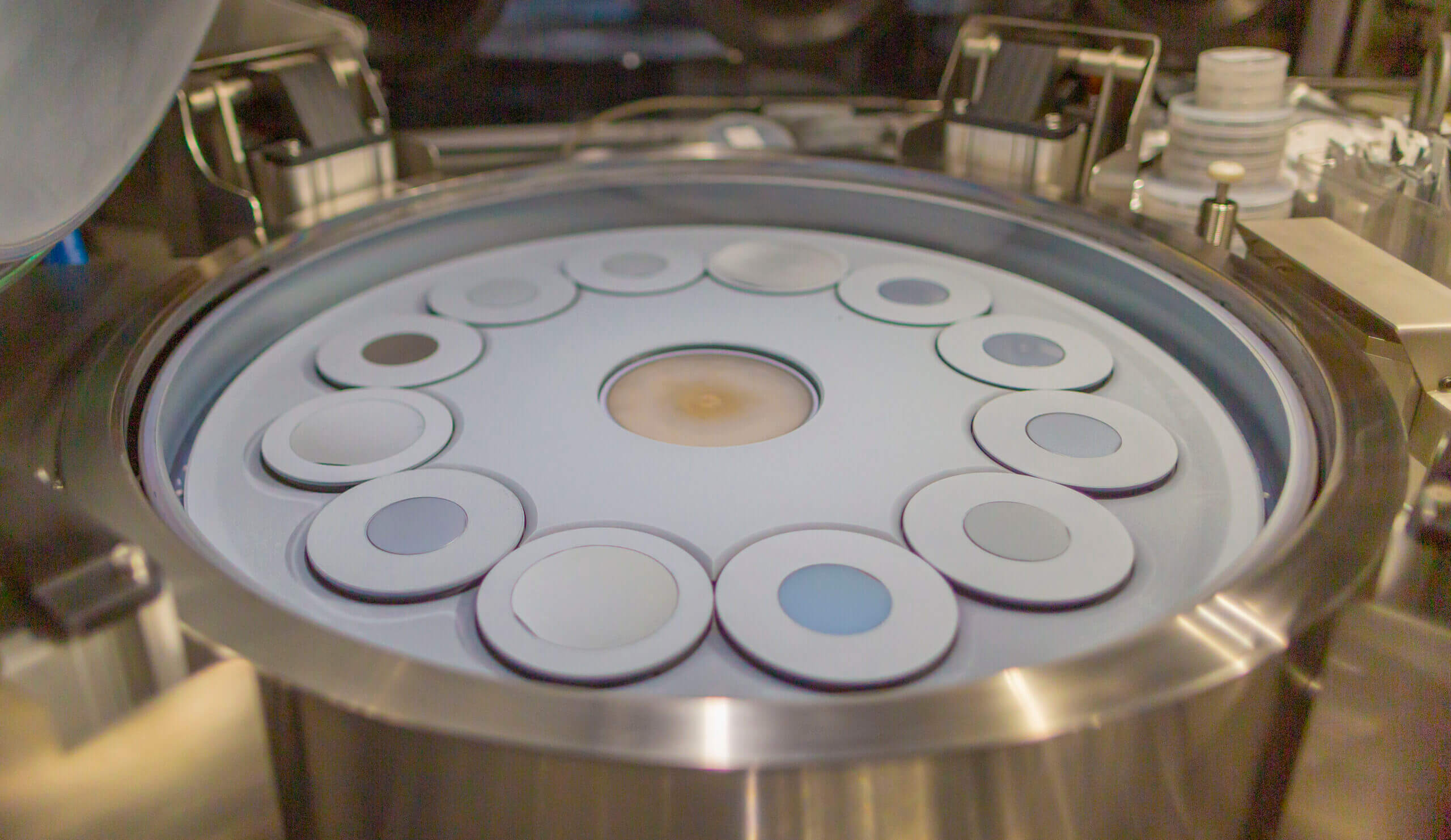

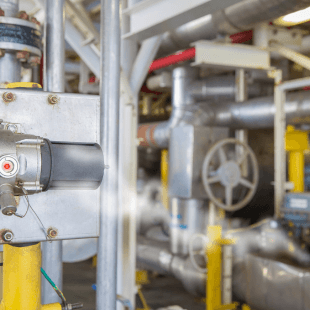

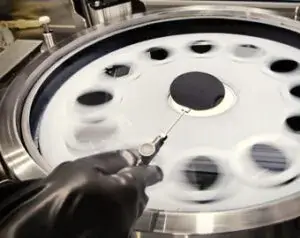

VIGO Photonics is a European manufacturer of epitaxial wafers and instruments for photonics and microelectronics, specialized in MWIR and LWIR detectors and modules, produced with the use of internally-developed technology.

37

years of experience

>220

employees

60

marketplaces

6

detectors on Mars

Strategy

and

Mission

The VIGO Photonics development vision assumes strengthening the Company’s position as one of the most innovative

and dynamically developing enterprises on the market.

Our goals include:

- Exploring the market of MCT (HgCdTe) detectors, including expansion (geographic, segmental) in market areas not covered by regulations, excluding the use of mercury and cadmium in detectors,

- Advances in the infrared detector technology and infrared modules made of materials based on compounds from groups III and V from the periodic table of elements, in line with the EU Restriction of Hazardous Substances (RoHS) directive,

- Advances in III-V semiconductor material epitaxy,

- Advances in infrared sources technology,

- The development of the optoelectronic systems technology and photonic integrated circuits for mid and short infrared,

- Advances in the infrared detector array technology.

Investor relations

Regular and transparent communication with all capital market participants is the key to our strategy of building sustainable value for the company on the stock market.

Learn more