Plastic Sorting Using Mid IR Linear Detector Array

Plastic Sorting Using Mid-IR Linear Detector Array

In the period of increased product supply, the quality of products delivered and the way they are presented become more and more important. Intelligent sorting is a mechanized solution that enables accurate sorting of products. The automation of the sorting process increases production capacity. This has a direct impact on profit, and, thus, on the quality and capacity of the products delivered.

Today, it is difficult to imagine a world without plastics - plastic objects are used in every area of our lives. The production of plastic products is much cheaper than the use of natural materials, moreover it is much faster thanks to advanced production methods. Plastics are materials that have been made by man from non-naturally occurring synthetic polymers or natural polymers (modified using appropriate additives). Colloquially, these types of materials are referred to as the collective name “plastic”, but you have to remember that this is a big simplification, which does not take into account the differences between individual types of polymer materials. The need of transparent, completely water resistant and with many other chemical factors raw materials turned out to be a turning point for the industry. This translated into a much greater availability and lower price of a single item.

Development of effective methods for the mass production of plastic objects has revolutionized many industries, but what about mass recycling methods?

Figure 1. Example of sorting plastic by using VIGO detectors.

Figure 2. The method of measuring plastic by FT-IR. The chart shows examples of absorption bands of various plastics

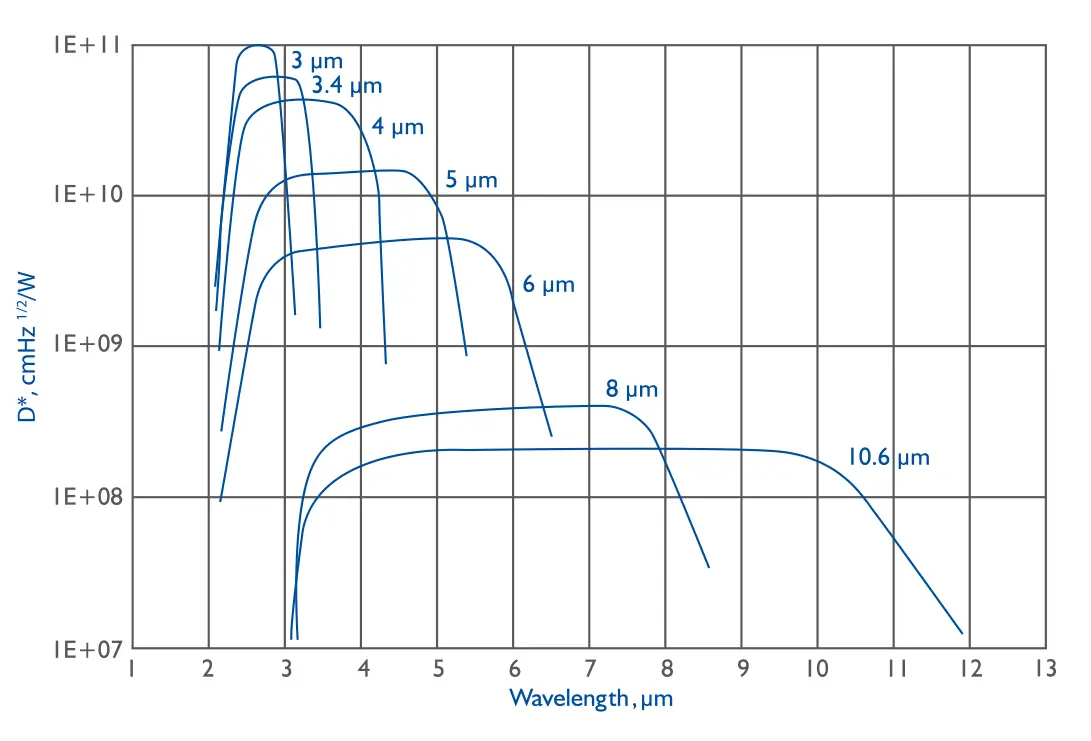

By detection of each marked absorption band the VIGO detector can “see” a type of the measured plastic.

Organic compounds like polymers can be observed more precisely in the MWIR range in comparison to the NIR range. The use of multielement detectors in spectrophotometry allows to eliminate moving parts or filters.

This simplifies the spectrophotometer and increases system reliability.

A 32-element linear array detector is recommended for OEM spectrophotometer for each polymer absorption band. Key benefits from using linear array detector include:

Elimination of moving parts and/or filters

High separation accuracy due to high SNR ratio

High speed measurement

Low power – uncooled detector

3-14 μm wavelength band

High S/N ratio

Low drift of output signals

High frequency operation

Module configuration options:

USB digital interface

Customized mechanical layout

Microprocessor inside

Figure 3. VIGO’s detector detectivity and some examples of absorption bands which can be used for plastic identification.

Chart 1. Exemplary spectral detectivity.

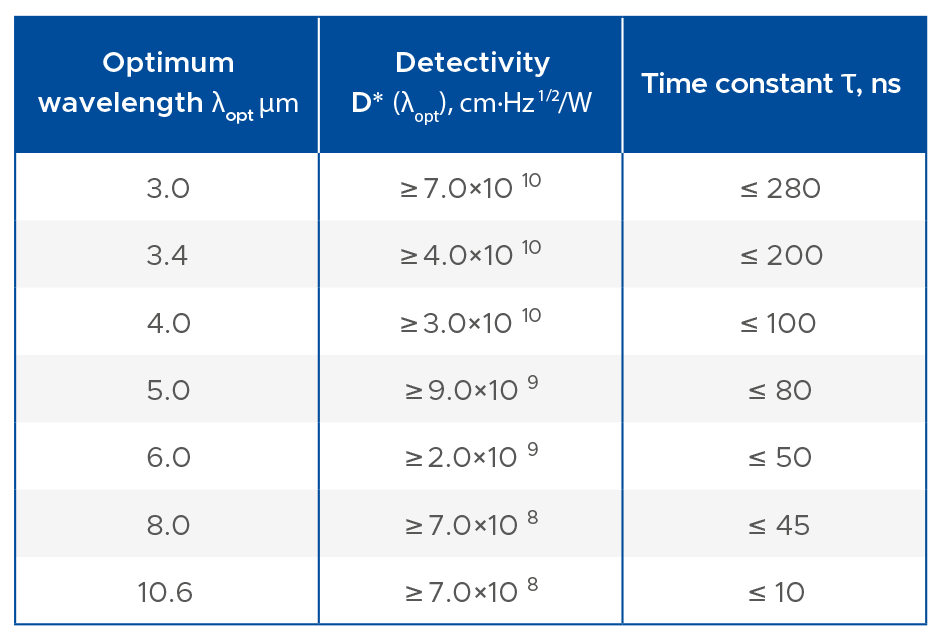

Table 1. Detectivity and time constant of HgCdTe detectors.

Our technological capabilities also allow the production of multielement detectors with InAsSb (indium arsenide antimonide) using the MBE (Molecular Beam Epitaxy) method.

These devices are complying with the RoHS Directive. They are designed for applications where higher resistance to difficult operating conditions should be ensured.

The great advantage of VIGO Photonics multielement detectors is that there is no need for cryogenic cooling. This results in a reduction in the size and weight of the device, and hence a reduction in power consumption.

Figure 4 shows the dimensions (unit: mm) of TO8 16pin (a) and flatpack 40pin (b) housings in which VIGO Photonics multielement detectors are mounted.

Figure 4. Mechanical layout.

Advantages:

High sensitivity

High-speed response

Convenient cryogenic-free operation

Table 2. Parameters.

Table 3. Accessories.

Applications

Multielement detectors are used in point, non-contact temperature measurements of fast moving elements. Real-time monitoring of temperature of external and internal wheel headings and high-speed train brakes can serve as an example. Other applications include: temperature measurements on production lines, anomalies detection, monitoring of cooling or combustion profiles etc.

Currently, available spectrophotometers usually use the near infrared range of 0.8 - 2.5 μm. Organic compounds, greenhouse gases, hydrocarbons can be more precisely observed in the MWIR (3.0 - 8.0 μm) and LWIR (8.0 - 14.0 μm) ranges. The use of multielement detectors allows to eliminate the need for filters or use moving mechanical elements for scanning the spectra or space, and, consequently, eliminates errors related to their work. VIGO Photonics multielement detectors allow for high quality spectrophotometric measurements in a short time and very low noise also allows for operation with low-power sources: thermal or IR diodes.

High performance optical sorting systems are another application of multielement detectors. The detector line scans elements moving on the tape and allows their specific chemical composition to be identified. Optical sorting can be used in the mining, food, chemical and pharmacological industries.